The process of liquid silicone rubber (LSR) molding has become a cornerstone in modern manufacturing, offering unique properties that other materials cannot match. This highly versatile technique is gaining traction across various industries, appealing to businesses aiming for durable, flexible, and efficient production solutions.

Understanding LSR Molding

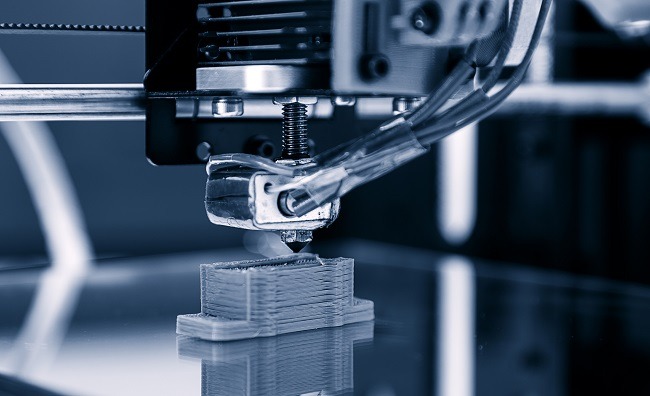

LSR molding is a state-of-the-art process that involves injecting liquid silicone into a mold to create high-quality molded components. The liquid nature of silicone before vulcanization is essential, allowing it to be used in intricate and precise mold designs.

Key Advantages of LSR Molding

- Durability: The end products are highly durable, resistant to extreme temperatures, and can withstand harsh environmental conditions.

- Flexibility and Precision: Ideal for creating complex shapes with tight tolerances, which is beneficial for medical and automotive applications.

- Biocompatibility: Safe for human use, making it perfect for healthcare-related products.

- Cost-Effectiveness: High repeatability reduces wastage and improves production efficiency.

Applications of LSR Molding

This technology is crucial in several areas due to its adaptable nature:

- Medical Devices: Used in products like catheters, syringes, and seals due to its non-toxic properties.

- Automotive Components: Provides durability and heat resistance for seals, gaskets, and other parts.

- Consumer Goods: Widely used in kitchenware, electronics, and other household items for its safety and flexibility.

Frequently Asked Questions

What is the main difference between LSR and traditional rubber molding?

LSR molding utilizes a liquid form of silicone, which allows for greater design flexibility and precision, unlike traditional rubber that requires solid or semi-solid forms.

How environmentally friendly is the LSR molding process?

The process generates minimal waste and the materials used are often recyclable, making it an environmentally sustainable option.

For an in-depth look at LSR molding services, visit the LSR molding page at Fox Mold.