How thermal transfer ribbon technology delivers fast, durable, lab-quality photos

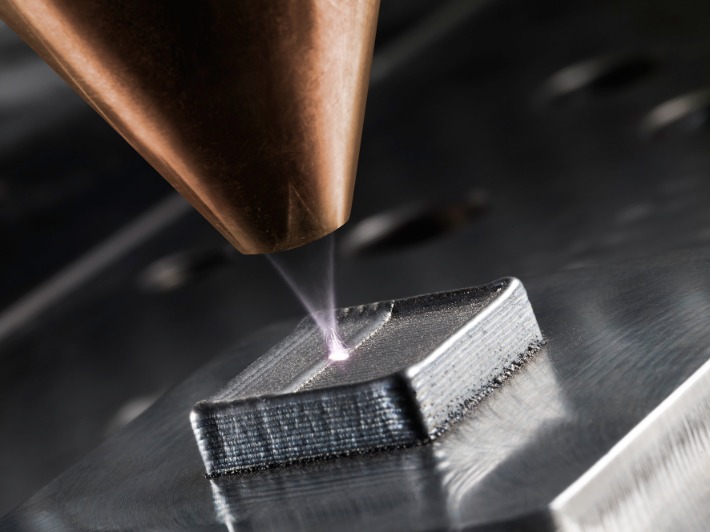

A thriving photo booth lives or dies by print quality and speed. At the heart of both sits the thermal transfer ribbon, the consumable that enables dye-sublimation printing to produce sharp, instantly dry, fingerprint-resistant photos. Unlike inkjet, which sprays liquid droplets, dye-sub uses a ribbon coated with solid dyes in sequential panels—typically Y, M, C, and an O (overlay), often labeled YMCKO. A precision thermal head heats the ribbon so the dyes vaporize and infuse into the specially coated paper, forming continuous-tone images that mimic chemical lab prints without the mess or drying time.

This process explains why dye-sub prints are so consistent for event work. The ribbon/paper combination is engineered as a matched system, yielding predictable color, a glossy or luster finish, and a clear protective overlay layer that resists water, UV, and smudging. Because the dyes diffuse into the paper, gradations are silky smooth, with skin tones that feel natural and highlights that don’t band. The overlay also means no waiting for curing or lamination—guests can pick up their keepsake seconds after it lands in the catch tray. For high-traffic activations, weddings, or retail kiosks, this reliability is the difference between a delighted line and a frustrated queue.

Cost control is equally predictable. Each ribbon is rated for a fixed number of prints at specific sizes (for example, 4×6 or 6×8), so operators can forecast cost-per-print precisely. There is no partial consumption; if one panel is used, the whole YMCKO set advances, which keeps output uniform but punishes inefficient layouts. Smart workflows minimize waste: choose output sizes that match your event needs, leverage built-in cutters for dual 2×6 strips when appropriate, and keep an eye on ribbon yields. When paired with good ICC profiles and a calibrated workflow, a high-quality thermal transfer ribbon helps deliver consistent color from the first print to the last roll, even under the unpredictable lighting and power conditions of live events.

What to look for in a photo printer for photo booth environments

Speed, durability, and media flexibility define a dependable booth printer. Start with throughput: look at rated seconds-per-4×6 and real-world sustained output, not just burst speed. A difference of five seconds per print can translate into dozens more guests served per hour during peak demand. Duty cycle and ribbon capacities matter too; bigger capacities reduce mid-event swaps and the risk of downtime. Media versatility—4×6, 5×7, 6×8, and automatic cutting for dual 2×6 strips—adds value for weddings, corporate activations, and branded campaigns. A strong cutter mechanism is essential for clean strips that don’t curl or jam, while integrated print queue management helps avoid bottlenecks when multiple capture stations are feeding one device.

Color accuracy and consistency separate pro event output from casual prints. Look for robust driver support, reliable ICC profiles, and the ability to fine-tune density for different papers and finishes. The overlay in dye-sub protects against moisture and UV, but not all coatings look the same—gloss, luster, and matte overlays can change perceived contrast and saturation. Mechanical considerations also count: a compact footprint, manageable weight for transport, front-loading paper paths for tight booth setups, and stable performance on portable power. Connectivity should cover USB and, ideally, reliable network options for multi-station rigs. For guidance and procurement, pairing with an experienced provider who understands event logistics can streamline your choice of photo printer for photo booth and consumables, ensuring everything clicks from day one.

Total cost of ownership goes beyond the sticker price. Factor ribbon yields at your most common sizes, waste from test prints, and the impact of overlays on longevity. Consider maintenance expectations—cleaning cycles, head life, dust management in high-traffic venues—and access to fast support. Backup plans are prudent: carry at least one spare printer for mission-critical activations, enough ribbons to exceed expected volume by 20–30%, and pre-cut spares for popular output formats. When the hardware, thermal transfer ribbon, and workflow are matched, the result is a smooth guest experience and images that feel as premium as the event itself.

Real-world booth workflows and case studies that boost throughput and quality

Consider a 200-guest wedding with a two-hour peak reception. Assuming 70% participation and two prints per session (a keepsake for guests and a copy for the couple), you might need 280–320 4×6 outputs in that window. A well-tuned dye-sub unit producing a 4×6 in 10 seconds theoretically delivers 360 prints per hour; real-world numbers are lower due to handoffs and queueing, so plan on 220–280. Many operators deploy two printers in parallel to load-balance bursts, especially when running a prop-heavy setup that encourages repeat visits. Preloading ribbon and paper, standardizing templates, and using auto-crop for 2×6 strips keeps the line moving while retaining that polished, lab-grade look.

Now zoom in on a brand activation targeting data capture and social sharing. The strategy might emphasize 6×8 prints for higher perceived value, branded frames, and a QR on the overlay for campaign tracking. Here, speed still matters, but color consistency and durability drive impact—the overlay ensures prints survive being passed around and photographed for stories. A sound workflow includes locked exposure in-camera to avoid inconsistent skin tones, a calibrated preset matched to the printer/paper combo, and batch-queued layouts. Staff coordination is pivotal: one person handles props and staging, another manages the print queue and ribbon swaps, and a third engages participants for consent and giveaways while prints finish. This choreography transforms the printer into a seamless part of the activation instead of a bottleneck.

At tourist venues or pay-per-print stations, predictable margins depend on precise cost-per-print and minimal downtime. Dye-sub’s fixed-yield thermal transfer ribbon simplifies pricing, while the rugged build of event-focused printers resists dust, vibration, and heavy hands. Real-world best practices include: staging ribbon and paper in climate-stable cases to prevent curl, scheduling quick head-clean cycles during natural lulls, and using analytics to measure prints per hour, reprint rates, and ribbon change time. Many operators keep prebuilt presets for “bright midday,” “warm indoor tungsten,” and “cool LED stage” lighting to maintain skin tone continuity across sessions. The outcome is a repeatable, professional standard—photos that wow on first glance and remain vibrant long after the event lights go out.