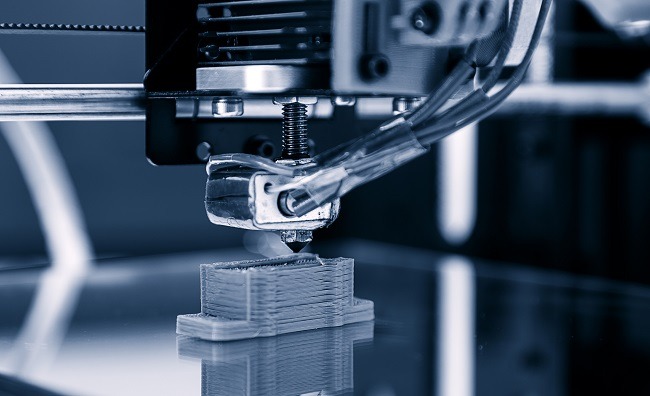

As technology continues to advance, additive manufacturing has emerged as a game-changer in various industries. One of the key components in this innovative process is In718 powder, a high-strength nickel-based superalloy known for its excellent mechanical properties.

What is In718 Powder?

In718 powder is a type of powdered metal that is used in additive manufacturing processes such as selective laser melting (SLM) and electron beam melting (EBM). It is composed of nickel, chromium, and other elements that give it exceptional strength, corrosion resistance, and heat resistance.

Benefits of Using In718 Powder in Additive Manufacturing:

- High Strength: In718 powder is renowned for its high tensile strength and fatigue resistance, making it ideal for applications that require durable components.

- Corrosion Resistance: The corrosion resistance of In718 powder makes it suitable for use in harsh environments where traditional materials may degrade over time.

- Heat Resistance: In718 powder can withstand high temperatures without losing its mechanical properties, making it suitable for aerospace, automotive, and oil and gas applications.

Read more about Inconel 718 Powder here.

Frequently Asked Questions about In718 Powder:

- Is In718 powder expensive?

In718 powder can be more expensive than other materials due to its high-quality properties and specialized manufacturing processes. However, the cost is often justified by the superior performance and longevity of components produced with In718 powder. - Can In718 powder be recycled?

Yes, In718 powder can be recycled and reused in the additive manufacturing process, making it a sustainable choice for manufacturers looking to reduce waste and minimize environmental impact. - What industries can benefit from using In718 powder?

Industries such as aerospace, automotive, oil and gas, and medical can benefit from using In718 powder due to its high strength, corrosion resistance, and heat resistance properties.

Overall, In718 powder is a groundbreaking material that is revolutionizing additive manufacturing by enabling the production of high-quality, complex components with exceptional performance characteristics. Its versatility and durability make it a popular choice among manufacturers looking to push the boundaries of traditional manufacturing methods.